A Guide To Polishing: What Polishing Wheel To Use For Which Material

What Are Polishing Wheels?

Polishing Wheels, also known as buffing wheels, provide a smooth and clean finish to metals, plastics, jewellery, glass, ceramic, wood, etc. They are mounted on polishing and grinding machines and rotated at high speeds to acquire the desired finish. Different types of polishing and grinding wheels are used for other purposes and have different results.

To get the desired finish, you must use the correct polishing wheel. However, that isn’t the only substance required for the final product. The process is two-fold. The first step is choosing the correct polishing/grinding wheel, and the second is associating it with the proper polishing compound. The polishing compound must be spread evenly on the wheel, and then the wheel, now coated with the compound, together to help you reach your end product.

Different Types Of Polishing Wheels And Their Applications

Polishing Wheel |

Image |

Applications |

| Cotton and Muslin |  |

· General Polishing: Ideal for general-purpose buffing and polishing of metals, plastics, and other materials.

· Final Finishing: Used for achieving a high gloss finish on surfaces. · Jewellery Making: Commonly used in jewellery making to polish and finish precious metals like gold and silver. · Automotive: Used for polishing car bodies, chrome, and aluminium surfaces. |

| Felt |  |

· Precision Polishing: Excellent for precision polishing where a higher degree of control is needed.

· Glass and Stone: Polishing glass, marble, and other stone surfaces. · Metal Polishing: Suitable for polishing metals to a high shine, including steel, stainless steel, and aluminium. · Abrasive Compounds: Often used with abrasive compounds for more aggressive polishing. |

| Satin/Matte |  |

· Satin Finishes: These are used to create satin or matte finishes on metals and other materials.

· Deburring: Effective for deburring edges and surfaces of metal parts. · Surface Preparation: Prepares surfaces for further finishing processes such as painting or plating. · Aesthetics: Provides an aesthetic finish for architectural and decorative purposes. |

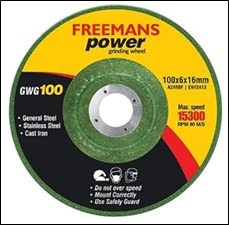

| Aluminium Oxide |  |

· Aggressive Cutting: Suitable for aggressive cutting and material removal.

· Hard Metals: Used for polishing and finishing hard metals such as stainless and high-carbon steel. · Surface Cleaning: Effective for cleaning oxidised or corroded surfaces. · Tool Sharpening: Commonly used in tool sharpening and blade honing applications. |

| Silicon Carbide |  |

· Hard Material Polishing: Ideal for polishing and grinding hard materials like ceramics, stone, and glass.

· Aggressive Material Removal: Effective for rapid material removal and shaping. · Non-Ferrous Metals: Suitable for non-ferrous metals such as aluminium, brass, and bronze. · Surface Preparation: Used for surface preparation tasks before finishing. |

| Nylon and Wire Wheels |  |

· Surface Cleaning: Used for cleaning and removing rust, paint, and other surface contaminants.

· Deburring: Effective for deburring and edge blending on metal parts. · Texturing: Can be used to create a textured surface finish on metals and other materials. · Woodworking: Nylon wheels can be used for surface finishing and texturing in woodworking. · Welding Preparation: Wire wheels are commonly used to prepare surfaces for welding by removing oxides and other contaminants. |

Different types of polishing compounds and their applications

Type of Compound |

Colour |

Abrasiveness |

Application |

| Tripoli Compound | Brown | Medium | · Used for the initial cutting and smoothing of metals.

· Effective on softer metals like aluminium, brass, copper, and nickel. · Removes light scratches and surface imperfections. |

| White Rouge | White | Light | · Provides a fine polish and smooth finish.

· Ideal for plastics, aluminium, and other soft metals. · Used for the final polish after a coarser compound. |

| Red Rouge | Red | Very Fine | · Designed for final polishing to achieve a high gloss.

· Often used on precious metals like gold, silver, and platinum. · Suitable for fine jewellery and delicate items. |

| Green Rouge | Green | Medium | · Used for a fine polish on hard metals like stainless steel and chrome.

· Effective on stainless steel and other hard metals for a mirror-like finish. |

| Black Emery | Black | Coarse | · Used for heavy cutting and initial polishing.

· Suitable for removing deep scratches and heavy oxidation. · Often used on iron, steel, and other hard metals. |

| Blue Rouge | Blue | Medium | · All-purpose compound for both cutting and colouring.

· Suitable for refined metals and plastics. · Provides a good balance between cutting action and final polish. |

| Brown Rouge | Brown | Medium | · Good for general-purpose metal polishing.

· Provides a smooth, reflective finish on various metals. |

| Zam | Green | Light | · Ideal for softer metals and plastics.

· Preferred for polishing aluminium and stainless steel. |

| Pink Rouge | Pink | Fine | · Used for a high-lustre finish.

· Effective on Gold, silver, and softer metals. |

| Stainless Compound | Grey or White | Medium | · Specifically formulated for stainless steel.

· Provides a brilliant finish without discolouration. |

| Diamond Compound | Varies | Very Fine | · Contains diamond particles for polishing rigid materials.

· Used for gemstones, ceramics, and hardened metals. |

Conclusion

In the end, it all depends on the material you are working with and the end result you desire. Whether you want a shiny, glossy finish or a matte finish, you can achieve them by choosing the right polishing wheel and its complementary finishing compound. Voila, you have your desired result right there in front of you.