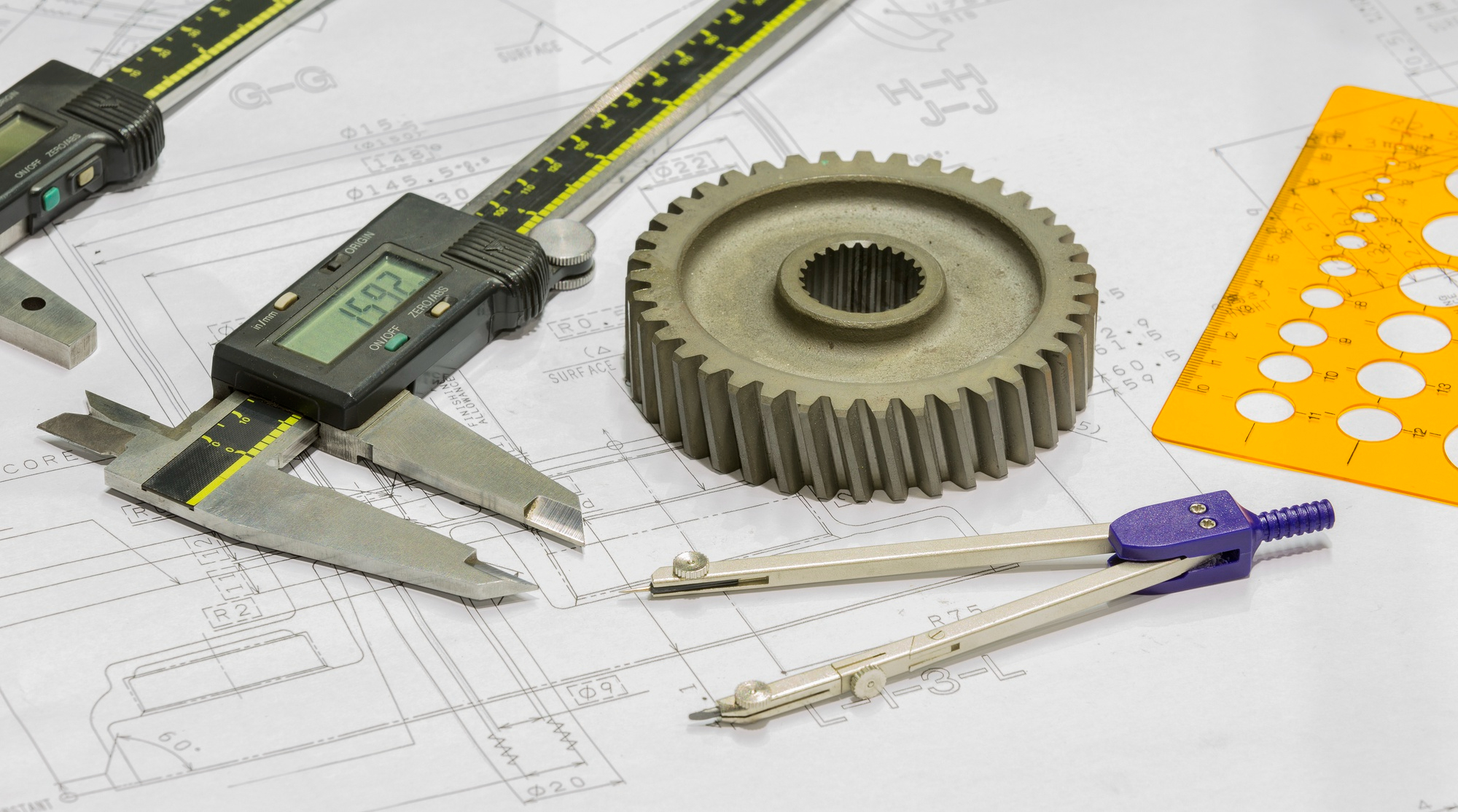

Callipers: The Precision Tools That Leave No Room for Error

A calliper, a precision instrument used to measure the distance between two opposing surfaces of an object, is a user-friendly tool in engineering, metalworking, woodworking, and other scientific professions. In this article, we will delve into the four main types of callipers: Vernier Callipers, Dial Callipers, Digital Callipers, and Micrometre Callipers, each designed for a specific measurement task, with features that make them easy to use and operate.

Different Types of Callipers

There are four main types of callipers: Digital Callipers, Vernier Callipers, Dial Callipers, and Micrometre Callipers.

Types of Callipers: Digital Callipers

A digital calliper has a digital dial which shows the reading. It has a minimum reading of 0.01mm or 0.0005in. A digital calliper has five major components:

- Jaws: The two arms of the calliper that come into contact with the measured object.

- Slider: The movable part of the calliper that adjusts the position of the jaws for measurement.

- Digital Display: Shows the measurement reading in digital format, typically to two decimal places or higher.

- Function Buttons: Allow for zero-setting, unit conversion, and locking the measurement.

- Depth Bar: An extension of one of the jaws used to measure holes or grooves’ depths.

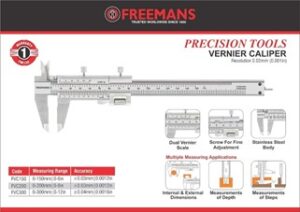

Types of Callipers: Vernier Callipers

Vernier callipers are named so because they use a Vernier scale to measure small distances. The Vernier calliper has two main parts for measurement. The Main scale measures in centimetres, and the Vernier scale has a minimum measure of 0.02mm or 0.001in. Other than that, there are six different parts of the Vernier calliper:

- Jaws: Two sets of jaws – an upper fixed jaw and a lower sliding jaw – come into contact with the measured object. The fixed jaw is stationary, while the sliding jaw moves along the main scale.

- Depth Gauge: A rod or blade attached perpendicular to the sliding jaw, used to measure holes or recesses’ depths.

- Locking Screw: A screw or knob that can be tightened to secure the sliding jaw in place once the measurement has been taken.

- Fine Adjustment Wheel (Optional): Some Vernier callipers feature a fine adjustment wheel that allows for precise adjustment of the sliding jaw’s position for accurate measurements.

- Main Scale Thimble: A part that moves along with the main scale and provides additional measurement reference.

- Vernier Scale Thimble: A part that moves along with the Vernier scale and provides additional measurement references.

Types of Callipers: Dial Callipers

A dial calliper has a circular dial, which is used to indicate the measurement. It is a precision measuring tool that measures the distance between the two opposite ends of a tool. A dial calliper has a minimum count of 0.03mm or 0.0012in. The major components of a dial calliper are:

- Scale or Ruler: The main body of the calliper has a graduated scale marked in metric (millimetres) and imperial (inches) units. This scale provides the measurement readings.

- Movable Jaw: The upper part of the calliper has a movable jaw that can be adjusted along the scale to measure the distance between two points.

- Fixed Jaw: The lower part of the calliper has a fixed jaw against which the measured object is placed.

- Dial Indicator: A dial indicator or gauge is attached to the main body that displays the measurement readings. It consists of a needle or pointer moving along a high-precision circular scale.

Types of Callipers: Micrometre Callipers

A micrometre calliper has a digital outside micrometre, which shows a minimum reading of 0.001mm or 0.00005in. Unlike the other callipers, a micrometre calliper can only measure the outside measure of an object. The object is placed between the anvil and the spindle, and the thimble is turned until it is fit against the two edges of the object. The digital display shows the measure of the object. The components of a micrometre calliper are:

- Frame: The main body of the micrometre, usually in a C-shaped or U-shaped design, which houses the other components.

- Anvil: The fixed part of the micrometre against which one end of the measured object rests.

- Spindle: The moving part of the micrometre that comes into contact with the other end of the object being measured. It moves parallel to the frame and is adjusted by the user to take measurements.

- Thimble: The outer cylindrical surface of the spindle, often knurled for better grip. The thimble is rotated to move the spindle and take measurements.

- Sleeve: The part of the micrometre housing the spindle and providing stability and support for its movement.

- Screw Mechanism: The mechanism inside the micrometre translates the rotational movement of the thimble into linear movement of the spindle. This mechanism typically consists of a finely threaded screw and nut.

- Scale: A calibrated scale, usually marked in millimetres and fractions of millimetres (sometimes in inches and fractions of inches), and attached to the frame. It indicates the measured distance when aligned with the edge of the thimble.

- Vernier Scale (optional): Some micrometres may feature a Vernier scale, which provides extra graduations for even finer measurements.

- Locking Device (optional): Some micrometres may include a locking device to temporarily fix the spindle in position once the measurement is taken, preventing accidental movement and ensuring measurement accuracy.

All of these different callipers have different uses, advantages and disadvantages.

Uses, Advantages and Disadvantages of Different Callipers

Type of Callipers |

Uses of Callipers |

Advantages of Callipers |

Disadvantages of Callipers |

| Digital Calliper | · Precision Measurement: Used for precise length, width, and depth measurements.

· Easy Readout: Provides digital readouts for quick and accurate measurements. · Conversion: Capable of converting measurements between metric and imperial units. · Data Recording: Some models have built-in data recording capabilities for documenting measurements. · Versatility: Suitable for various applications, including engineering, woodworking, machining, and hobbyist projects. |

· Accuracy

· Easy to use · Convenient · Versatile |

· Dependent on a battery

· Costly · Affected by moisture and temperature |

| Vernier Calliper | · Precision Measurement: Provides accurate length, width, and depth measurements.

· Fine Measurement: Capable of making fine measurements with its Vernier scale. · Outside Measurements: Used for measuring external dimensions of objects. · Inside Measurements: Using jaws or probes, it can also measure internal dimensions. · Depth Gauge: Includes a depth gauge for measuring the depth of holes and grooves. · Metalworking: Commonly used in metalworking, machining, and engineering applications. |

· Precision scale

· Durable · Versatile · Traditional design · No batteries required |

· Less precise

· Has a learning curve |

| Dial Calliper | · Precision Measurement: Provides accurate length, width, and depth measurements.

· Dial Readout: Features a dial indicator for reading measurements. · Easy Calibration: Can be calibrated for accuracy. · Smooth Movement: Offers smooth movement for precise positioning. · Inside and Outside Measurements: Can measure both external and internal dimensions. · Metalworking: Widely used in metalworking, machining, and mechanical engineering. |

· Highly accurate

· Durable · Smooth operation process · Easy to calibre · No batteries required |

· Fragile

· Complex to use |

| Micrometre Calliper | · High Precision: Offers exact measurements with high accuracy.

· External Measurements: Primarily used for measuring the external dimensions of objects. · Internal Measurements: Some models feature interchangeable anvils for measuring internal dimensions. · Depth Measurements: Can measure depth with its depth rod or blade. · Metalworking and Engineering: Commonly used in metalworking, machining, and engineering applications requiring high precision. |

· Can measure in micrometres

· Has a high resolution · Can measure internal, external and depth · Very durable |

· Costly

· Limited range · Specialised Use |

Conclusion

You can choose any of the above callipers, depending on the purpose and what you want to measure. While each of the callipers has its own set of advantages and disadvantages, you should consider the ease of use and your budget before making the decision of which is the best suited to your needs. If you have determined that you will be using the calliper for an extended period of time, investing in a high-quality calliper that will give you accurate readings with minimal error and is durable is your best bet.